English translation for this page is currently unavailable. We are working on it, stay tuned!

1 / 18

รายละเอียดสินค้า

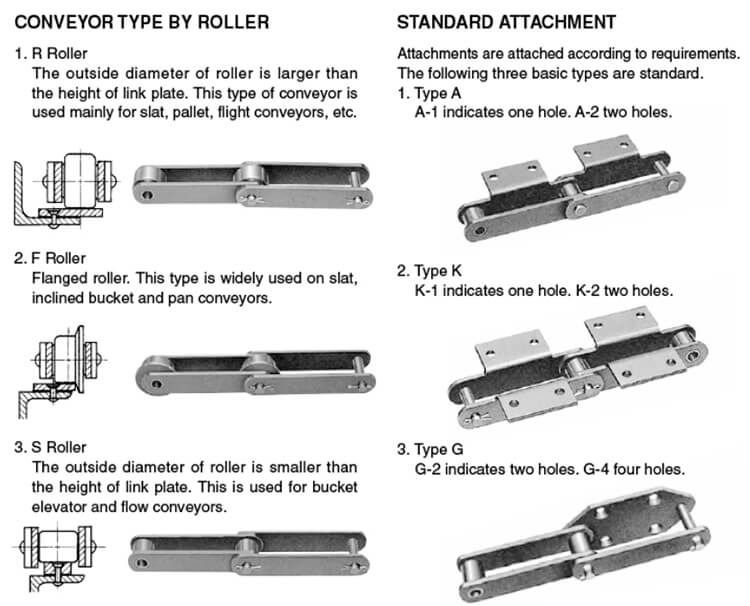

Construction of OCM Conveyor Chains ผลิตภัณฑ์จากประเทศ ญุี่ปุ่นThere are many type chains for conveyors applications but steelchains are popular and widely used. OCM FM and FE conveyors chains are superior to other type in strength wear-resistanceand characteristic that changes in material and attachmentsare readily according to applications.Conveyor Type by Roller1) R Roller The outside of diameter of roller is larger than the height of link plate. This type of conveyor is used mainly for slat, pallet, tight conveyor, etc.2) F Roller Flange roller. This type is widely used on slat, inclined bucket and pan conveyors.3) S Roller The outside of diameter of roller is smaller than the height of link plate. This is used for bucket elevator and tight conveyors.Standard AttachmentsAttachments are attached according to requirementThere are three basic types are standard.1) Type A, A-l indicates one hole, A-2 indicates two holes2) Type K K-1 indicates one hole, K-2 indicates two holes3) Type G-, G-2 indicates two holes, G-4 indicates four holes

Construction of OCM Roller ChainsRoller chain is made of roller link and pin linksRoller link consists of two bushing press-fitted into roller link platewith two free rotating rollers over the bushings. Pin link consists oftwo link plates into which two pins are press-fitted.There are two types of pins: Rivet (Spring Clips) and Cotters

1) Spring Clip (Rivet) This is standard for single and multiple strand ANSI standard chain 80 and below and British standard chain 16B and below2) Cotter Type This is standard for single and multiple strand ANSI standard chain 100 and above and British standard chain 20B and above3) Offset Link This is a combination of a roller link and a pin link This link is used when the chain length is odd number It is recommended not to be used an offset link whenever possible.4) Two Pitches Offset Link The unit consists of one offset link and one roller link Pins are press-fitted into the link plates, and the unit is more suitable for heavy impact load and high-speed driving than one pitch offset link

OCM Stainless Roller SUS SeriesThis chain is made of 304 (austenitic) stainless steel. This chainhas excellent corrosive resistance very low magnetic. \This chain is good for general acid, alkali, water, etc. Heat resistance.

OCM Stainless Roller SAC SeriesThis chain is made of 316 (austenitic) stainless steel.This is better in corrosive resistance than SUS Series andnon-magnetic. Spring clips and cotters used are made of304 stainless steel. Heat resistance.

OCM Stainless Roller SPH SeriesThe pin, bush and roller of this chains are made of 600 Se harriesprecipitation hardened stainless steel with link plate 0f 304stainless steel. Spring clips and cotters used are made of304 stainless steel. Magnetic, Better wear-resistanceThe working load of this chain is 1.5 SUS Series

OCM "DC" type and "TC" type Roller Chainsระบบ BS/Single Pitch/Heavy DutyDC type roller chain consists of twice the number of side platesas the single strand chain as the working load is close to thestandard double strand chain "DC" type and "TC" type roller chains run on standard roller chains sprockets and ideal chainspeed less than 50m/min.

OCM "H" (Heavy Duty Roller Chain)ระบบ ANSI/Single Pitch/Heavy Duty"H" type roller chains have increase link plate thickness to providegreater capacity without failure fatigue. The link plate thicknessis that of the next larger size chains. Single strand roller chainof "H" type run on standard roller chain sprockets.

OCM Hollow Pin Double Pitch Chains (โซ่แบบลูกกลิ้งใหญ่)ความยาว 3 เมตร จำนวน 1 เส้น แถมฟรีข้อต่อเต็มข้อ จำนวน 1 ตัวHollow Pin Roller Chain No. 2042 HP, 2052 HP, 2062 HPOCM 2082 HP แบบลูกกลิ้งใหญ่ โซ่แกนกลวง โซ่ดับเบิ้ลฟิทช์แบบลูกกลิ้งใหญ่ โซ่อุตสาหกรรม โซ่ HKH

OCM Corrosion Resistance Roller Chains (โซ่ทนต่อการกัดกร่อน)ระบบ ISO/ASME/ANSI/DIN Standardโซ่สำหรับต่อการกัดกร่อนใช้กรรมวิธีพิเศษในการบำบัดพื้นผิวสำหรับชิ้นส่วน หรือใช้ชิ้นส่วนที่ทำจากพลาสติควิศวกรรม ฯลฯ สแตนเลส ฯลฯเพื่อให้ได้มีความทนทานต่อการกัดกร่อนได้ดีเยี่ยมเป็นไปตามมาตรฐาน ISO/ANSI/DIN และมาตรฐานอื่นๆ

OCM Coupling Chains (ยอยโซ่)ประกอบด้วย ยอยโซ่ จำนวน 2 เส้น และ ตัวยอย จำนวน 1 ชุด

OCM Apron Conveyor ChainsThis OCM apron conveyors is ideal for conveying bulk materialssuch as chips made by machine tools. Side Chains are OCM standard conveyor chains. OCM standard sprocket can be used.

OCM FVC (Hollow Pin Conveyor Chains) is a type of conveyor chainsdesigned for conveying materials in various industries.These chains features hollow pin which offer advantages

OCM โซ่เหล็กแบบ Specialty (โซ่เหล็กสั่งทำพิเศษ)OCM Products three different types 81X chain: "81XH"and "81XH-S. Each type is designed with different link platethickness and heights to strength progressively higher load, durability

OCM แบบ HP (Hollow Pin Chains) ANSI/SINGLE PITCHHP type chains are constructed with cold-forged solid bushings.This process assures that the inside diameter of the bushing'shollow center is completely cylindrical all the way through

OCM โซ่ลำเลียงแท่งอลูมิเนียม1) มีความแข็งแรงสูง ความเมื่อยล้าสูง และอายุการใช้งานยาวนาน2) ทนทานต่อการสึกหรอ ทนต่อแรงกระแทก

OCM TR (Top Roller Chains)ระบบ ANSI/Single Pitch/AttachmentTR (Top Roller Chains) type roller chains are based on OCM standardroller chains with extra rollers mounted on top of the chainTop rollers are installed on the pin that connect SK-1 extendedattachment plates. The rollers are available in OCM 40-1TR

OCM ND SELUBE CHAINSsubject to special treatment has been improved its wearresistance more than 4 times compare with OCM SELUBE CHAINin the ordinary temperature range. It is suitable to extend the time for replacement of SELUBE chains, it is possible to replacewithout facilities equipment's changesอ่านเพิ่มเติม

Construction of OCM Roller ChainsRoller chain is made of roller link and pin linksRoller link consists of two bushing press-fitted into roller link platewith two free rotating rollers over the bushings. Pin link consists oftwo link plates into which two pins are press-fitted.There are two types of pins: Rivet (Spring Clips) and Cotters

1) Spring Clip (Rivet) This is standard for single and multiple strand ANSI standard chain 80 and below and British standard chain 16B and below2) Cotter Type This is standard for single and multiple strand ANSI standard chain 100 and above and British standard chain 20B and above3) Offset Link This is a combination of a roller link and a pin link This link is used when the chain length is odd number It is recommended not to be used an offset link whenever possible.4) Two Pitches Offset Link The unit consists of one offset link and one roller link Pins are press-fitted into the link plates, and the unit is more suitable for heavy impact load and high-speed driving than one pitch offset link

OCM Stainless Roller SUS SeriesThis chain is made of 304 (austenitic) stainless steel. This chainhas excellent corrosive resistance very low magnetic. \This chain is good for general acid, alkali, water, etc. Heat resistance.

OCM Stainless Roller SAC SeriesThis chain is made of 316 (austenitic) stainless steel.This is better in corrosive resistance than SUS Series andnon-magnetic. Spring clips and cotters used are made of304 stainless steel. Heat resistance.

OCM Stainless Roller SPH SeriesThe pin, bush and roller of this chains are made of 600 Se harriesprecipitation hardened stainless steel with link plate 0f 304stainless steel. Spring clips and cotters used are made of304 stainless steel. Magnetic, Better wear-resistanceThe working load of this chain is 1.5 SUS Series

OCM "DC" type and "TC" type Roller Chainsระบบ BS/Single Pitch/Heavy DutyDC type roller chain consists of twice the number of side platesas the single strand chain as the working load is close to thestandard double strand chain "DC" type and "TC" type roller chains run on standard roller chains sprockets and ideal chainspeed less than 50m/min.

OCM "H" (Heavy Duty Roller Chain)ระบบ ANSI/Single Pitch/Heavy Duty"H" type roller chains have increase link plate thickness to providegreater capacity without failure fatigue. The link plate thicknessis that of the next larger size chains. Single strand roller chainof "H" type run on standard roller chain sprockets.

OCM Hollow Pin Double Pitch Chains (โซ่แบบลูกกลิ้งใหญ่)ความยาว 3 เมตร จำนวน 1 เส้น แถมฟรีข้อต่อเต็มข้อ จำนวน 1 ตัวHollow Pin Roller Chain No. 2042 HP, 2052 HP, 2062 HPOCM 2082 HP แบบลูกกลิ้งใหญ่ โซ่แกนกลวง โซ่ดับเบิ้ลฟิทช์แบบลูกกลิ้งใหญ่ โซ่อุตสาหกรรม โซ่ HKH

OCM Corrosion Resistance Roller Chains (โซ่ทนต่อการกัดกร่อน)ระบบ ISO/ASME/ANSI/DIN Standardโซ่สำหรับต่อการกัดกร่อนใช้กรรมวิธีพิเศษในการบำบัดพื้นผิวสำหรับชิ้นส่วน หรือใช้ชิ้นส่วนที่ทำจากพลาสติควิศวกรรม ฯลฯ สแตนเลส ฯลฯเพื่อให้ได้มีความทนทานต่อการกัดกร่อนได้ดีเยี่ยมเป็นไปตามมาตรฐาน ISO/ANSI/DIN และมาตรฐานอื่นๆ

OCM Coupling Chains (ยอยโซ่)ประกอบด้วย ยอยโซ่ จำนวน 2 เส้น และ ตัวยอย จำนวน 1 ชุด

OCM Apron Conveyor ChainsThis OCM apron conveyors is ideal for conveying bulk materialssuch as chips made by machine tools. Side Chains are OCM standard conveyor chains. OCM standard sprocket can be used.

OCM FVC (Hollow Pin Conveyor Chains) is a type of conveyor chainsdesigned for conveying materials in various industries.These chains features hollow pin which offer advantages

OCM โซ่เหล็กแบบ Specialty (โซ่เหล็กสั่งทำพิเศษ)OCM Products three different types 81X chain: "81XH"and "81XH-S. Each type is designed with different link platethickness and heights to strength progressively higher load, durability

OCM แบบ HP (Hollow Pin Chains) ANSI/SINGLE PITCHHP type chains are constructed with cold-forged solid bushings.This process assures that the inside diameter of the bushing'shollow center is completely cylindrical all the way through

OCM โซ่ลำเลียงแท่งอลูมิเนียม1) มีความแข็งแรงสูง ความเมื่อยล้าสูง และอายุการใช้งานยาวนาน2) ทนทานต่อการสึกหรอ ทนต่อแรงกระแทก

OCM TR (Top Roller Chains)ระบบ ANSI/Single Pitch/AttachmentTR (Top Roller Chains) type roller chains are based on OCM standardroller chains with extra rollers mounted on top of the chainTop rollers are installed on the pin that connect SK-1 extendedattachment plates. The rollers are available in OCM 40-1TR

OCM ND SELUBE CHAINSsubject to special treatment has been improved its wearresistance more than 4 times compare with OCM SELUBE CHAINin the ordinary temperature range. It is suitable to extend the time for replacement of SELUBE chains, it is possible to replacewithout facilities equipment's changesอ่านเพิ่มเติม

- สภาพสินค้ามือหนึ่ง

- ลงขายเมื่อ14 ธ.ค. 2568 14:34 น.

- ตำแหน่งประกาศวังทองหลาง กรุงเทพมหานคร

- หมายเลขประกาศ371134142

กรุณาอย่าโอนเงินไม่ว่ากรณีใดๆ

หากต้องการโอนเงินหรือมัดจำล่วงหน้าตรวจสอบบัญชีคนโกง ที่นี่

หากต้องการโอนเงินหรือมัดจำล่วงหน้าตรวจสอบบัญชีคนโกง ที่นี่

สินค้าที่คุณอาจจะสนใจ'

ดูเพิ่มเติมคำค้นหาที่เกี่ยวข้อง

เกี่ยวกับ kaidee

ศูนย์ช่วยเหลือ

บริษัทในเครือ

ติดต่อเรา

เลขที่ 554/117 อาคารสกายไนน์ เซ็นเตอร์ ชั้น 22 ถนนอโศก-ดินแดง แขวงดินแดง เขตดินแดงบริษัท เคดี มาร์เก็ตเพลส จำกัด (สำนักงานใหญ่)กรุงเทพมหานคร 10400

© 2568 บริษัท เคดี มาร์เก็ตเพลส จำกัด